JNI Armor is a leader in supporting defense products to our nation’s

warfighters and law enforcement officers.

Capabilities include:

Capabilities include:

Research and

Development

JNI Armor specializes in the research and development of advanced transparent armor products, solutions, and technologies. Our engineering team has 20+ years of experience in product development and funded development research. Areas of expertise for funding include:

- Ballistic Modeling

- Life Prediction and Durability Modeling

- Transparent Armor

- Structural Composite Armor

- Embedded Ceramic Armor

Transparent Armor

JNI Armor is a leader in transparent armor and bullet resistant glass for military, law enforcement, and security forces. Focus areas include:

- Advanced Materials

- Lightweight Solutions

- Durability

We are currently developing solutions to increase durability. This includes working with the government, vehicle manufacturer’s, and other transparent armor companies to get superior solutions for our nation’s defenses.

Armor Products

JNI Armor is a distributor of armor products to armor industry and government. This includes:

- Armor Cutting Tools

- Ballistic Shield Components

- Viewports

- Ballistic Shield Lights

- Bandsaw Blades

We support various facets of the armor industry through our extensive network!

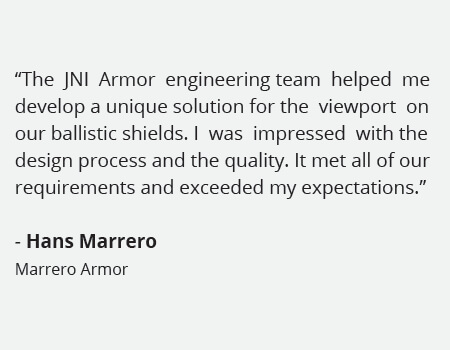

The Right Partner

JNI Armor’s goal is to work with the best in the business to support our nation’s freedoms. This includes developing strategic partnerships with other defense companies… and sometimes competitors, to protect those that protect us.

It works! See what some of our partners say:

JNI Armor is at the forefront of developing durable transparent armor for the military through a $1.5M Phase II SBIR funded by the USMC.

JNI Armor is working with vehicle manufacturers and other transparent armor companies to develop better solutions to our warfighters. In a short period of time, we have developed multiple Phase III production programs with our advanced technologies:

- Extending Life

- Increasing Ballistic Performance

- Reducing Lifecycle Costs