Solutions/ Applications

Military Transparent Armor

JNI Armor is at the forefront of developing durable transparent armor for the military through a $1.5M Phase II SBIR funded by the USMC.

JNI Armor is working with vehicle manufacturers and other transparent armor companies to develop better solutions to our warfighters. In a short period of time, this has developed multiple Phase III production programs with technologies:

- Extending Life

- Increasing Ballistic Performance

- Reducing Lifecycle Costs

Transparent Armor Programs

- Tactical Vehicle

- Forced Entry

- Blast Resistant

- Ballistic Shields

- Navy Vessels

- Rotorcraft

- Specialty Vehicles

- School Armor

Capabilities

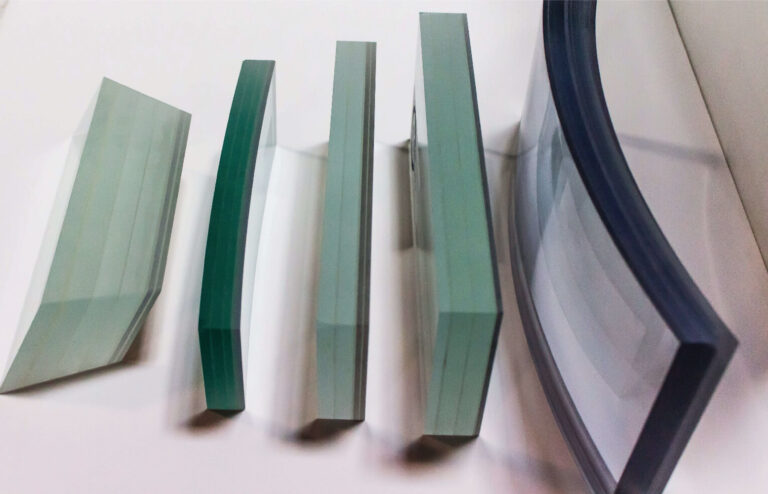

- Chemical Tempering

- Heat Strengthening / Tempering

- Lamination (up to 60” x 120”)

- 5 Axis Waterjet

- Armor Design

- Research and Development

- Armor Integration

Why Choose JNI Armor?

- Most Durable >5 Years Lifetime

- Delamination Resistant Technologies

- Advanced Materials

- Lightweight Solutions

- Ballistic Modeling

- Life Prediction and Durability Modeling

- Structural Composite Armor

- Embedded Ceramic Armor

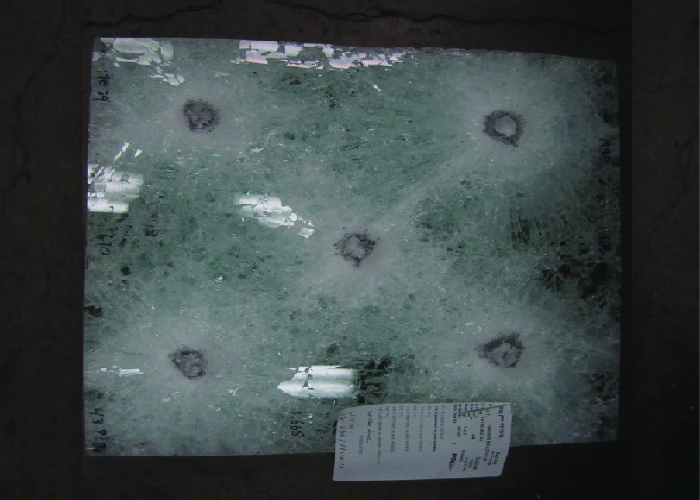

JNI Armor has developed efficient processes and advanced technologies to increase the lifetime of the transparent armor.

- Lamination Technologies

- Edge Seal Systems

- Interlayer Adhesives

- Glass Coatings

- Reduce Mud/Rain

- Reduce Solar Heat of Windows

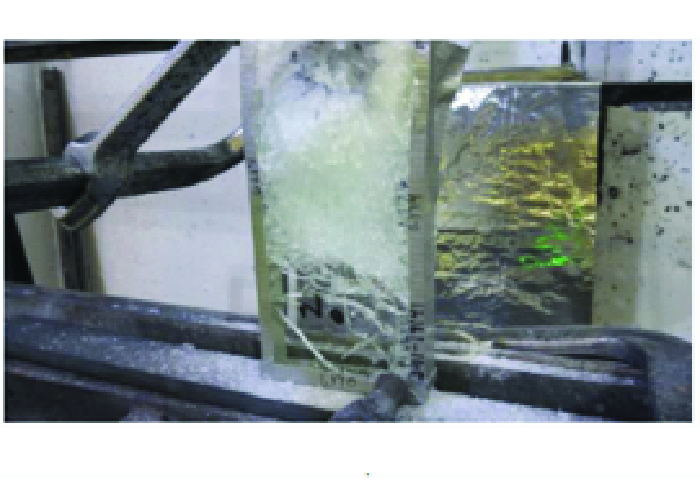

JNI Armor has specialized Extreme Climate technologies designed for resistance to delamination in high temperature, humidity, and cold temperature environments.

Technologies can be integrated into flat or curved glass for military or commercial vehicles to defeat CEN 1063, NIJ 108.01, STANAG 4569 requirements, or any threat requirement.

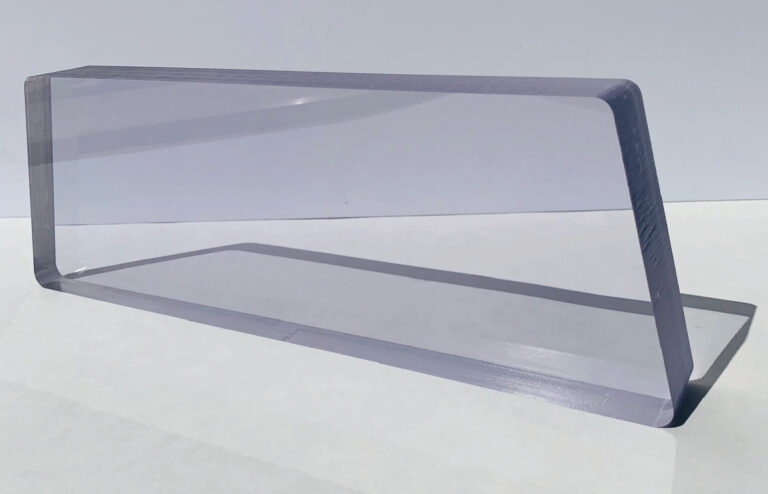

Advanced Lightweight Transparent Armor for Tactical Vehicles

- ATPD 2352 tested

- Advanced Materials

- >5 year lifetime

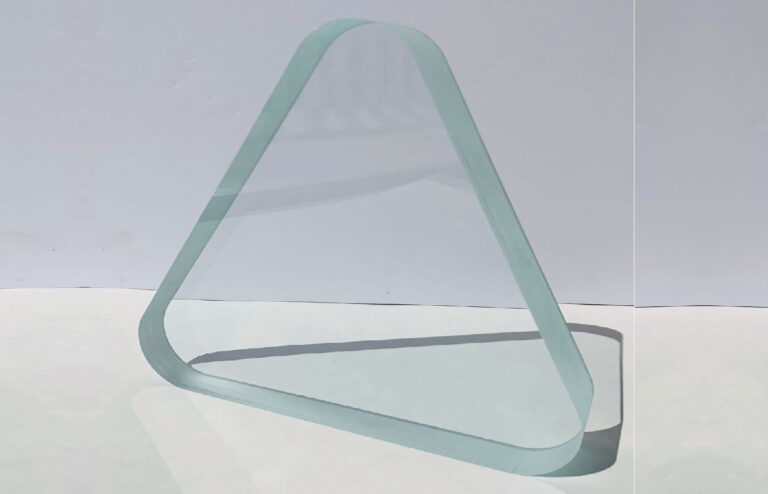

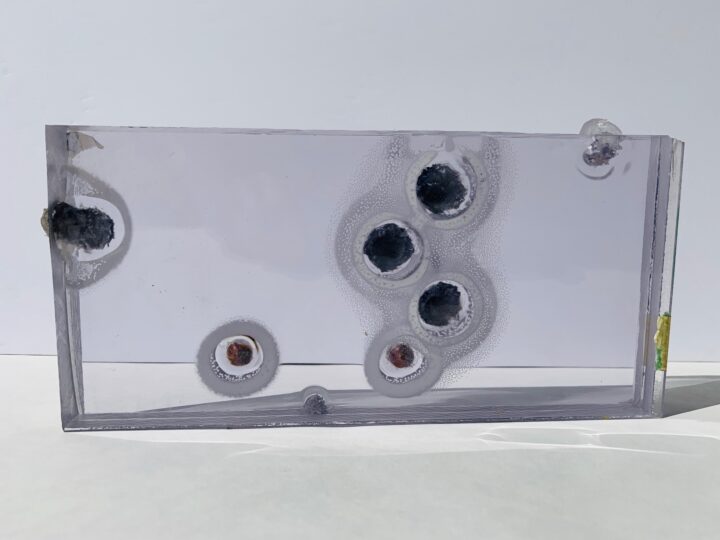

Viewports for Ballistic Shields

JNI Armor has developed efficient processes to

produce ballistic viewports for police shields. Our engineering

team can develop ballistic viewports according to your specifications,

or we can develop custom viewport solutions. The JNI Armor

engineering team is here to help innovate, develop, and protect by

creating the best solutions that will save lives.

JNI Armor can produce various viewport shapes:

- Flat

- Curved

- Triangle Shaped

- Custom Shapes

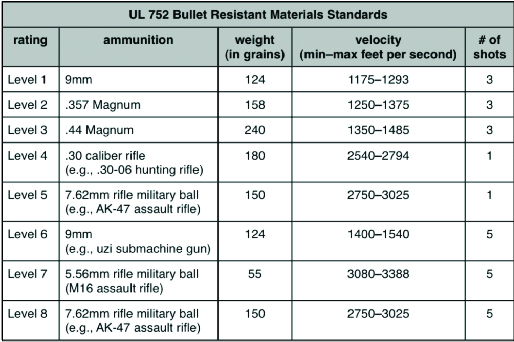

JNI Armor’s viewports can be designed to defeat any threat requirement including:

- NIJ IIIA

- NIJ III

- NIJ III+

- NIJ IV

- Custom Solutions

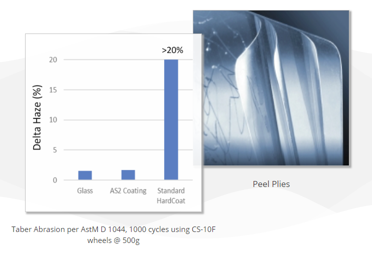

JNI Armor Advanced Technologies

- Delamination Resistant Solutions

- Monolithic Polymer Systems

- Peel Plies for Scratch Repair

- Enhanced Hard Coat for Polycarbonate

Armor for Schools

JNI Armor Commitment

"JNI Armor has made a commitment to focus on protecting future generations and support safer school environments by providing the highest quality bullet resistant products. We can make a major difference in the community by protecting the growth our future. We are here to help!"

Le Nguyen

CEO

Bullet resistant glass (or transparent armor) for high schools, middle schools, and elementary schools is becoming more paramount. JNI Armor has over 20 years of experience in developing transparent armor to meet the most demanding environments and budgets. We are dedicated to helping communities protect their future generations.

JNI Armor applications include

exterior and interior doors and windows using insulated glass

technology. Bullet resistant glass can be designed for bullet

resistance up to armor piercing threats and for forced entry

requirements.

Forced Entry Bullet Resistant (FEBR) and Blast Resistant

JNI Armor works with Oregon Ballistics Lab (OBL) and their team of forced entry test experts in developing armor solutions. We can develop solutions to meet any state department requirement.

JNI Armor’s Forced Entry Bullet Resistant (FEBR) solutions can be designed for resistance to any requirement including armor piercing threats. The JNI Armor team can work with you on custom solutions to protect your home, business, or vehicles.

Solutions with greater than 2 hr penetration resistance